معلومات ذات صله

استشر الولايات المتحدة

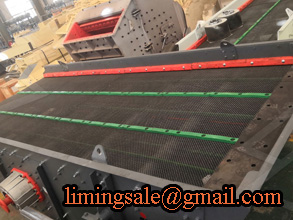

بصفتنا مصنعًا عالميًا رائدًا لمعدات التكسير والطحن ، فإننا نقدم حلولًا متطورة وعقلانية لأي متطلبات لتقليل الحجم ، بما في ذلك إنتاج المحاجر والركام والطحن ومحطة تكسير الحجارة الكاملة. نقوم أيضًا بتوريد الكسارات والمطاحن الفردية وكذلك قطع غيارها.

Process flow of a conveyor belt system ResearchGate

The conveyor belt system consists of several groups of conveyor belts, for example, the Qgroup, Pgroup, Dgroup, Egroup, Ngroup, or more A onemonth realtime electricity consumptionUsage example Slide contents: Conveyor belt process flow chart step steps Conveyor Belt Production Line Graphics for illustrating specific processes, like product launch, orLong conveyor belt process flow chart with 7 Steps infoDiagram

Flow chart for the threestep method | Download

This paper discusses a model of a belt conveyor with a dynamic change in the angle between the horizontal plane and the plane of the conveyor belt The model is given by a nonlinear system of fourConveyor Belt Group Flowchart of mining, processing, combustion of coal and further utilisation or disposal of fly ash at a mining and power plant company 1 Coal mining &Conveyor Belt Solutions Continental Industry Contitech PDF

Conveyor Belt Solutions for every mining task

ContiTech supplies a wide range of special underground one or twoply conveyor belts (eg standard PVG and PVC belts), one or twoply fabric belts (eg CONMONTEX E/PThe belt conveyor can work in the range of temperature 20 –40 C and can transport all kinds of bulk materials with temperatures lower than 60 C, such as ne pow fi der,Belt Conveyor, Structure and Principle Classification of

Fig 1 The system block diagram of the belt conveyor

Aiming at solving the problem of high energy consumption in the rated belt speed operation of a belt conveyor system when the material flow rate is reduced, the power2022年8月1日· The flow chart depicted in Fig 6 shows the process used for failure detection due to misalignment of the conveyor belt system For this system, video of theHealth monitoring of a conveyor belt system using machine vision

Schematic diagram of mechanical conveyor belt drive

Belt drives refer to mechanical friction transmissions with a flexible connection and are used if it is necessary to transfer the load between shafts located at considerable distances TheConveyor Belt Production Line Graphics for illustrating specific processes, like product launch, or use such visuals for creating timelines and flowcharts6 stages conveyor belt loading process showed with

Conveyor Belt Process Flow PowerPoint Template SlideUpLift

ConveyorBeltProcessFlow 16x9 – $499 Add to Cart Buy Membership Also available in Google Slides Add to Favorite Rating: ★ ★ ★ ★ ★ Download 100% editable Conveyor Belt Process Flow PowerPoint Template to visualize your presentation content effectivelyBelt Conveyors are also a great option to move products through elevations Incline Belt Conveyors from low to high and Decline Belt Conveyors from high to low This manual is short, with quick and easy reading paragraphs, very practical for calculations of belt, chain conveyors and mechanical miscellaneous, in the metric and imperial systemBelt Conveyor for Bulk Materials Practical Calculations

The flow chart of system | Download Scientific Diagram

Download scientific diagram | The flow chart of system from publication: A Contactless Measuring Speed System of Belt Conveyor Based on Optical Flow Techniques | In mining operation, measuringA Flowchart is a graphically representation of the process, algorithm or the stepbystep solution of the problem There are ten types of Flowcharts Using the Flowcharts solution from the Diagrams area of ConceptDraw Solution Park you can easy and quickly design the Flowchart of any of these types Conveyor Belt Symbol In Process Flow SheetHow to Create a Cross Functional Flow Chart ConceptDraw

Belt Conveyors: Components, Types, Design, and Applications

For applications that may require the “unorthodox” width greater than the length, type of conveyor, modular belt conveyors will achieve that feat much easier Since they are nonmetallic, easy to clean, and porous to gas and liquids, modular belt conveyors can be applied in: Food handling Fluid handlingBelt conveyors play an important role in continuous dry bulk material transport Large scale belt conveyor systems consume a considerable amount of electrical energyFlow chart for the threestep method | Download Scientific

Materials conveyors: A guide for specifying belt conveyor systems

2021年1月26日· equation Where: C = Conveyor capacity r = Material density (kg/m3) V = Belt speed (m/s) A = Conveyor’s belt crosssectional area Belt speed should be specified such that it does not cause spillage of the raw material being conveyed Suitable conveyor belt speed typically ranges between 25 m/s and 35 m/sBelt Capacity Chart The Following conveyor belt capacity charts show tons per hour (TPH) based on = 03 x Belt Speed (FPM) x material weight (lb per cu ft) x load cross section (sq ft) TPH with 20° Troughing Idlers Belt Width in Inches Belt Speed in feet per minute (FPM) 100 150 200 250 300 350 400 450 500 550 600 650 16 42Belt Capacity Chart Pooley Inc

Conveyors Belt Speed The Engineering ToolBox

Maximum conveyor belt speed Sponsored Links Typical maximum conveyor belt speeds for products like Grain and Free Flowing Material Mine Coal and Earth Primary Crushed Hard Ores and Stone are indicated in the charts below: Sponsored LinksBelt Conveyor Catalog Phone: (308) 3247591 Fax: (308) 3247549 sales@conveyusa TOLL FREE: wwwconveyusa 18776642687 It is the responsibility of the contractor, installer, owner and user to install, maintain and operate the conveyor, components andBelt Conveyor Catalog Orthman

Conveyor Belt Solutions Continental Industry Contitech PDF

Conveyor Belt Group Flowchart of mining, processing, combustion of coal and further utilisation or disposal of fly ash at a mining and power plant company 1 Coal mining & conveying Short & longdistance conveying Coal stockpiling & transportation between mine and power plant in front of / to the power plant Pocket and sidewall belts Pouch belts1 Introduction Conveyor belts are a cost effective method of transporting bulk materials in many industries worldwide In the mining industry, conveyor belts are critical components of the supply chain, and the ability to estimate belt wear rates is important to ensure that risk of failure and maintenance activities are managed optimallyDeveloping and evaluating predictive conveyor belt wear models

Health monitoring of a conveyor belt system using machine

2022年8月1日· The flow chart depicted in Fig 6 shows the process used for failure detection due to misalignment of the conveyor belt system For this system, video of the conveyor belt was recorded using the camera and analyzed on a local computer Only the results of the analysis were transmitted to the cloud to save on transmission bandwidth2019年2月14日· To correctly material test a conveyor belt scale you should run three weighed material samples The first two tests are used to determine a repeatable error, if any Each material sample should be run across the conveyor belt scale continuously at a rate over 50% of the scale’s rated capacity You may find after the first two tests that theHow do you perform a material test on a conveyor belt scale?

Flow chart of the speed regulation of a belt conveyor

As an important transportation, the belt conveyor has been widely used and researched It is urgent to solve the problem of energy saving and consumption reduction of belt conveyor2021年4月12日· A conveyor belt is an automation process: it enables a machine to perform the role of multiple human laborers in delivering materials or goods from one location to another As such, this is the major, basic function of all the conveyors you see in the world This explains why conveyors look like they do and where they fit into aHow Do Conveyor Belts Work: A Comprehensive Guide

Interactive Calculator Kase Conveyors

CONVEYOR CAPACITY & SPEED CALCULATION: DESIGN CONDITIONS SPCL FLIGHT TYPE – Place an “x” in the appropriate box 1 Flowrate (m) : lb/hr 72017年10月20日· Figure 8: System flow chart Figure 9: Selector switch at station 2 position Belt conveyor design is examined as an application of a proposed Design Parameters Space Search technique(PDF) Design and Fabrication of PLC Based Conveyor System with

WBS 3 homewoek Read and Complete 3 Conveyor Belt Studocu

Read and Complete 3 Conveyor Belt Project Case Part 3, Embry Riddle Aeronautical University May 10, 2020 Author Note This assignment is for PMGT 614 Directing and Controlling Projects Monte Carlo Simulation Results The data below in Figure 1 shows the Monte Carlo results for the Conveyor ProjectContribute to naicha22/2022 development by creating an account on GitHub2022/ conveyor belt process flow chartmd at main GitHub